Changzhou BYMAY Metal Technology Co., Ltd. of Germany to introduce the latest technology and production technology, production of the two-European licensing ceramic aluminum veneer, high scratch aluminum alloy aluminum plate is a surface coating on a substrate aqueous ceramic coating (nano inorganic resin) by heat curing methods, and forming properties similar to ceramic film (coating), it is also known as nano-ceramic aluminum, is the latest green materials, keeping the other aluminum veneer performance, more durable (9H), fire prevention, environmental protection, anti-static, anti-bacterial, self-cleaning nano, hardness, corrosion resistance, weatherability 50 years long, long life, etc., belong to the third generation of aluminum curtain wall panels.

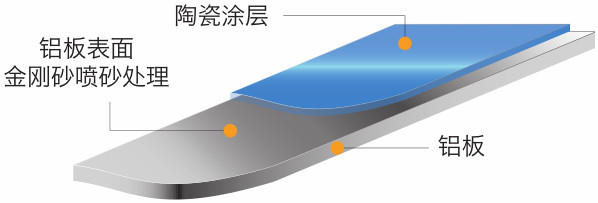

Aluminum plate for the substrate:

The company selected 3003H24,5005H24 single aluminum plate for the substrate, the thickness of 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm, 4.5mm, 5.0mm thickness, and other molded aluminum sheet sizes up 2400x6000mm.

structure:

Mainly by the ceramic coating, panels, stiffeners, mounting brackets and other components, in response to customer requirements, can be filled in the back panel of mineral wool insulation, ribs, lugs can be bent directly from the panel, the panel also on another installation.

In order to ensure the strength of the aluminum alloy plate flatness and long-term use, we are equipped to strengthen the tendons in the back of the plate by a bolt to the ribs and the panel is connected to as a solid overall, thereby increasing its strength and rigidity.

feature:

1. The latest green materials

It does not produce any toxic odors, gases, and harmless to the environment, non-toxic, non-polluting, high-performance security.

2. Inorganic Nanomaterials

The use of nano inorganic resin as the main base material, selection of high hardness and wear resistance of nano metal oxide, silica, high weather inorganic pigments, through a special process from the preparation, the aluminum substrate surface after coating, forming an inorganic ceramic coating, nanometer material level.

3. Physical and chemical properties

High hardness (room temperature hardness 6-9H), high abrasion (abrasion> 20,000 times)

4. Chemical properties

High-strength acid, alkali, salt, solvents, corrosion

5. Long service life, long weather resistance

Ultra Kubo color, anti-chalking, anti-aging, weathering long (50 years), anti-atmospheric pollution

6. The height of the self-cleaning properties

Eliminate static electricity, non-stick, not prone to electrostatic dust, washed by rain natural purification, holding curtain wall facade cleaning, facade cleaning cost savings, high degree of self-cleaning.

7.A1 fire performance level

High temperature> 600 ℃, non-flammable, A1 class fire.

8. The third generation of aluminum curtain wall

Nano-aluminum, aluminum fluorocarbon beyond application performance, called "third-generation aluminum curtain wall," is the preferred owners and designers.

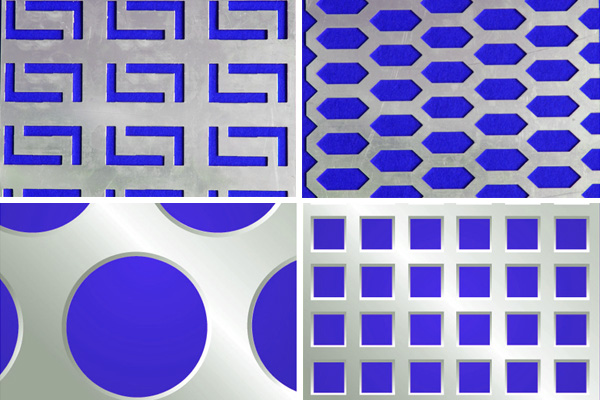

application

BYMAY nano-ceramic aluminum is widely used in subway, high-speed rail, light rail station hall, platform decoration, hospitals, shopping malls, hotels, railway stations, stadiums, exhibition halls, airports, office buildings and other indoor and outdoor decoration, building walls and appliances surface coating , environmentally friendly, sterile, wear-resistant, fire protection requirements.

Production Process

Our company has introduced the most advanced production equipment and technology to improve product quality, create high-quality. At present, the introduction of the German LFK CNC sheet metal equipment group, with more than one computer numerical control cutting machines, bending machines, engraving machines and the introduction of Japan AMADA CNC punch, and continuously improve the accuracy of the sheet metal workers and poor, to the yacht Sheet gold level. Henkel spraying equipment imported high-purity water pre-treatment system, Japan's automatic-electrostatic spray systems, natural gas combustion system, temperature control system, CNC fully automated production process.

Sheet metal production process

CNC Shears → → CNC punching sheet discharge line (angle of attack, slotted) → CNC bending (rollers arc) forming → Welding → assembly (ribs, angle code) → → → polishing grinding test (detection)

Spraying equipment and technical advantages:

Advantage 1: Germany Han high purity water pre-treatment system

Pre-treatment process

Washed thoroughly → degreasing (degreasing) → pure water washing → caustic (alkaline etching) → pure water washing → pickling (except light) → pure water washing → passivation → pure water washing → pure water washing → drying

Advantage 2: Japan's automatic electrostatic spraying system

It is the world's most advanced electrostatic spraying equipment, the use of "X-axis and Y-axis" automatic computer control system, automatic electrostatic spray gun, the primer, paint, varnish (protective paint) computer ratio, effective control spray coating thickness uniformity, to reduce chromatic aberration to ensure product quality, nano-ceramic aluminum fluorocarbon aluminum veneer, aluminum ceilings, aluminum and other aluminum material spraying the best equipment, consistent access to the same industry praise and widely used nano-ceramic coatings, fluorocarbon paint spraying.

Spraying process

Spray paint on pieces → → → spray paint spray varnish (protective paint) curing → → → Test → next member film (packaging) → warehousing

3 advantages: natural gas combustion system, furnace temperature control system

BYMAY technology companies by Japanese standards established by the nano-ceramic coatings, fluorocarbon paint spraying production line length of 350 meters, where the natural gas combustion systems, temperature control systems up to 100 meters, the longest in the industry, the largest nano-ceramic coating , fluorocarbon paint spraying production line one. Application of this technology features: the spraying process takes about 150 minutes, in which the coating products under 200 ℃ high temperature curing for 45 minutes to allow the coating is completely cured coating to ensure the technical parameters indicators meet or exceed standards AAMA2605-05 requirements, effectively enhance the spraying product adhesion, weather resistance, durability and stability, gloss and color retention, and prolong life.